It seems that the adventure of each trip to Harris starts long before I even get to the ferry. This time it wasn’t storms or blizzards, but trying to get my poor overladen car out of the car park in Fort William…when there wasn’t even enough room to get the gear stick into reverse! The solution entailed getting out of the car, unpacking the passenger seat into the car park, reversing, repacking the passenger seat, then setting off…praying that it would be – literally – a straightforward journey thereafter!

Thankfully, there were no more awkward reversing moments, and the next morning it was up early to meet Jonathan, Project Manager Extraordinaire, off the Uist ferry.

Thankfully, there were no more awkward reversing moments, and the next morning it was up early to meet Jonathan, Project Manager Extraordinaire, off the Uist ferry.

Despite the horrendous weather this winter – with two storms recording over 110mph – great progress has been made by Angus and Murdo Sam on the stonework.

You need to take time to admire and absorb the details…the lovely wobble in the chimney, the tightness of the curved reveals to the windows, the fact that the straight windows have been made to look curved…

You need to take time to admire and absorb the details…the lovely wobble in the chimney, the tightness of the curved reveals to the windows, the fact that the straight windows have been made to look curved…

…and the marram grass roof is nearing completion, the next stage being to form a latticework of rope, fringed with the stones,which will secure the thatch against the prevailing winds.

Inside, Chris the plasterer was busy getting to grips with the ceiling…

Inside, Chris the plasterer was busy getting to grips with the ceiling…

…meanwhile we spent a great deal of time assessing the challenge of laying the entrance hall floor with Innes, who is taking on all the tiling. Innes is Angus the master boatbuilder’s son. While we’re on the genealogy of Oran Na Mara, I may as well explain that Kenny and Iain MacKay (the joiners) are brothers, and their father, Kenny Senior, is the Site Manager and (together with Jonathan, who isn’t related) Solver of All Problems. Norman is Kenny Senior’s brother and he dug the foundations. Neil is also Kenny’s brother and operates the digger. Don John is brother to Neil, Kenny Senior and Norman, and Uncle to Kenny and Iain, and he is the weaver of beautiful tweeds….more on that later, but meanwhile, back to the entrance floor…

This is going to be a mosaic formed with the beautiful flat Gneiss stones collected from the beach, with sand sprinkled on the cement grout while it’s still wet, then all sealed and protected with Lethifin. (the photo shows an experimental sample with the door). It reflects the surroundings in more ways than simply bringing in the stones and sand from the beach…

This is going to be a mosaic formed with the beautiful flat Gneiss stones collected from the beach, with sand sprinkled on the cement grout while it’s still wet, then all sealed and protected with Lethifin. (the photo shows an experimental sample with the door). It reflects the surroundings in more ways than simply bringing in the stones and sand from the beach…

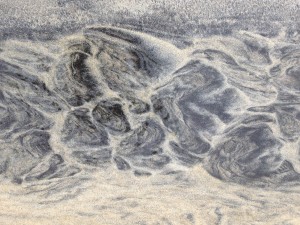

This is the pattern made in the sand by a river rippling over it and down to the sea at Luskentyre…

This is the pattern made in the sand by a river rippling over it and down to the sea at Luskentyre…

…and this is the striking pattern formed by lichen marking out its boundaries on a gravestone in St. Clement’s churchyard at nearby Rodel.

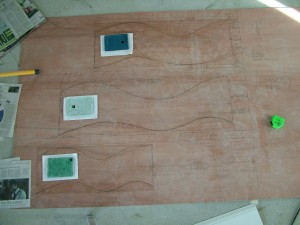

One of the corridors is backed by the utility room wall and has no natural light, so we’re fitting three textured and coloured glass panels…land, sea and sky.

The glass panels are being made as rectangles, so I had to make templates of the shapes, which Kenny and his sons will cut out of the plasterboard walls before inserting the glass and finishing with 6mm. plasterboard, bent to form the curved “sills” and reveals.

More templates – this time for the seating area. The difficulty with a curved sofa is that the back will be so much longer than the front, so I had to make sure that there was sufficient room for a sofa that would comfortably seat three people – with chairs either side, still following the curve.

The most exciting part of this trip was my visit to Don John at Luskentyre Tweed – when I eventually found him. Having gone up and down the Luskentyre road two or three times, I eventually stopped at a house, whose owner said he was another 4 houses along. I counted carefully and rang the bell. ”Hello, Mr. McKay?” “Yes…?” “It’s Jane Blanchard” ”Yes??” “Your brother told you I was coming about some tweed???” ” Ah, you mean my neighbour, Mr. Don John MacKay – and we’re not related!”

The most exciting part of this trip was my visit to Don John at Luskentyre Tweed – when I eventually found him. Having gone up and down the Luskentyre road two or three times, I eventually stopped at a house, whose owner said he was another 4 houses along. I counted carefully and rang the bell. ”Hello, Mr. McKay?” “Yes…?” “It’s Jane Blanchard” ”Yes??” “Your brother told you I was coming about some tweed???” ” Ah, you mean my neighbour, Mr. Don John MacKay – and we’re not related!”

His tiny shed looks out over the machair and the shore, and these are the inspiration for the beautiful colours and designs that come from his loom. He has fulfilled orders for Nike and Chanel, and has an MBE for his service to the industry, but was more than happy to discuss our modest requirements, and kindly took the time to show me his loom, which is really the most incredible piece of engineering.

His tiny shed looks out over the machair and the shore, and these are the inspiration for the beautiful colours and designs that come from his loom. He has fulfilled orders for Nike and Chanel, and has an MBE for his service to the industry, but was more than happy to discuss our modest requirements, and kindly took the time to show me his loom, which is really the most incredible piece of engineering.

Even the simplest patterns are jewel like, because each yarn is made from several different colours – which you can’t make out with the naked eye, but have a look at this photo I took through a magnifying lens! I left with a treasure trove of samples, which I’ll be working on over the next few weeks….

Even the simplest patterns are jewel like, because each yarn is made from several different colours – which you can’t make out with the naked eye, but have a look at this photo I took through a magnifying lens! I left with a treasure trove of samples, which I’ll be working on over the next few weeks….